Gas springs are a popular alternative to mechanical leaf or coil springs as they offer increased product longevity and precision operation. While carbon gas springs are also popular, nitrogen is the most common actuation media used for these air springs and air shocks due to its abundance. Read More…

Isotech offers a complete line of gas springs for most applications. From steel to stainless steel AISI 303/304 and AISI 316/316Ti, Isotech has the right product for the job. Gas Springs include tension springs, locking gas springs, realease systems, oil dampers, double-stroke springs, and gas spring accessories. Contact us today for more information!

More Nitrogen Gas Spring Manufacturers

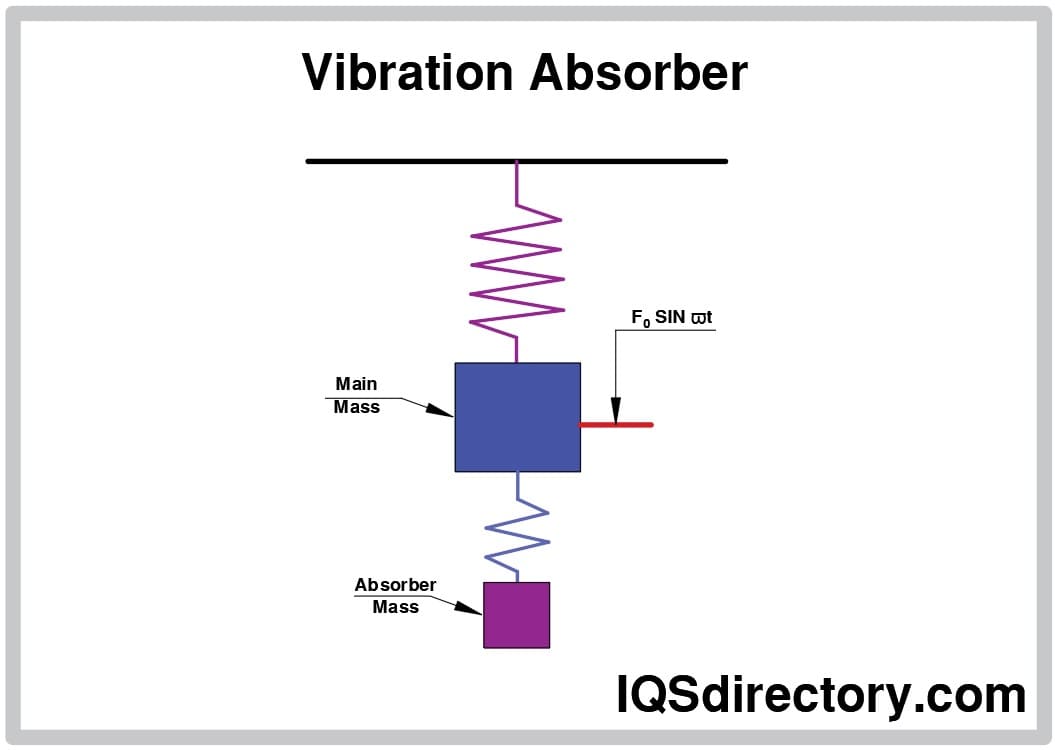

Nitrogen gas springs have naturally low reactivity, which allows them to be used in a number of applications, such as food and aerospace applications, without risk of explosion or harmful contamination. Marine, medical, commercial and manufacturing industries such as those using presses, die cutting, drawing or casting also make use of these devices in daily operations as they offer not only damping and shock absorption but force exertion as well.

gas lifts using nitrogen cylinders are likewise popular for platform or stock lifters. Nitrogen gas springs can offer forces anywhere between five and twelve hundred pounds, depending on size and construction. Despite the impressive mechanical capabilities and benefits associated with the use of nitrogen in gas springs manufacturing, caution should be taken when using compressed nitrogen in large amounts or improperly ventilated areas as the odorless, colorless chemical can act as an asphyxiant should the spring leak.

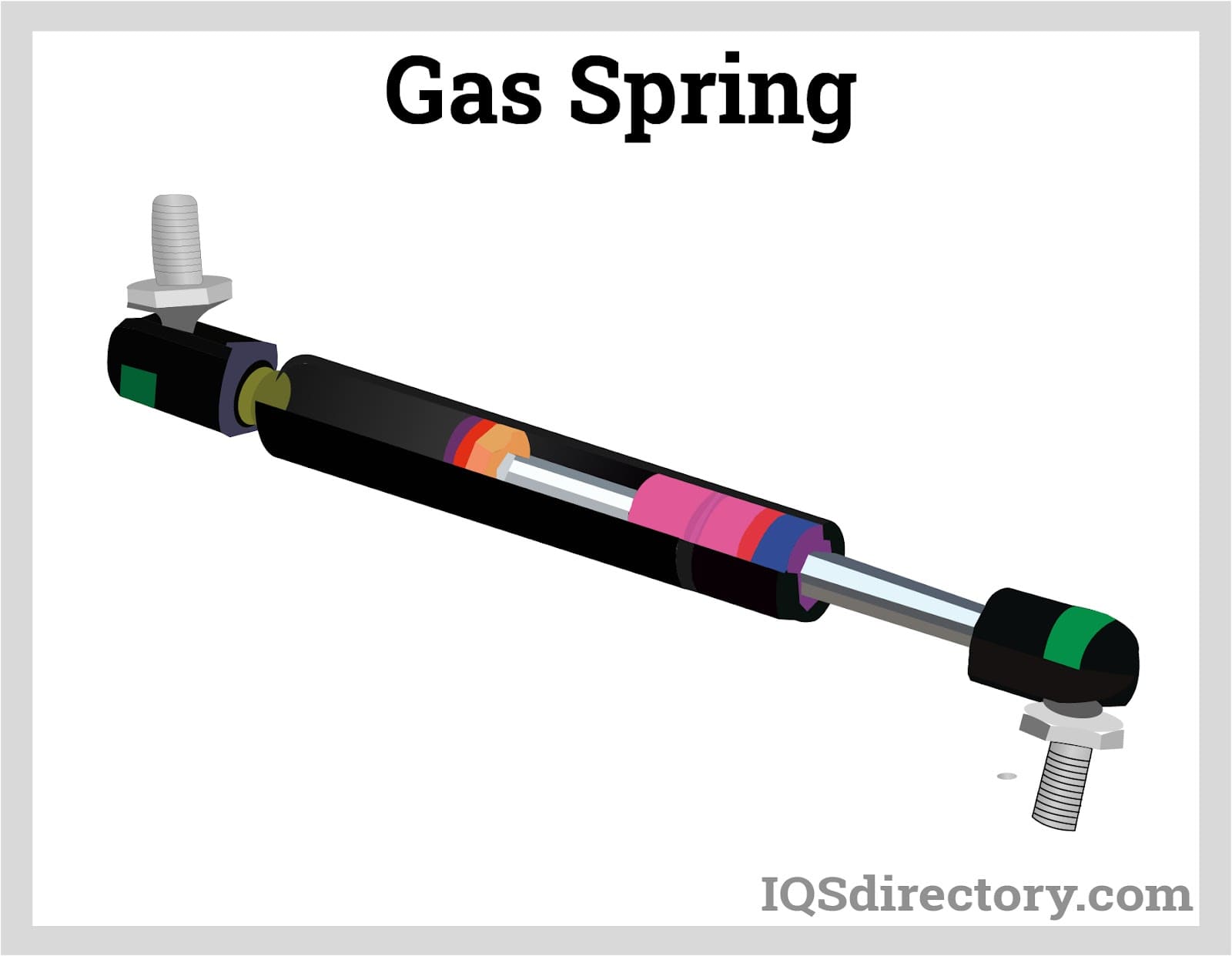

A self-contained cylinder, nitrogen gas springs are relatively simple in design, though additional features such as adjustable stroke length, locking mechanisms, high temperature seals, high speed extension and reduced compression ratios may necessitate more detailed design. For simpler models, a gas spring body is a sealed, tubular cylinder most commonly made of durable materials such as steel, stainless steel, aluminum or thermoplastics as needed to suit a specific application.

The interior surface is polished to micro-fine smoothness in order to reduce extraneous friction as the piston head slides up and down the barrel. The piston head and surrounding seals and o-rings divide the chamber into two airtight compartments. A rod is attached at one end to the piston head while the opposite end protrudes from the main body and attaches to the item to be supported or protected.

An orifice or valve is located on either end of the chamber to allow pressurized gas from a nitrogen reservoir to be introduced into or exhausted from the chamber as needed. This action causes the extension or compression of the spring. Alternatively, force on the piston rod causes the nitrogen to further compress and absorb energy as needed to protect surrounding equipment. To ensure precision functionality gas spring design often incorporates 3D CAD drawings and other software.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services