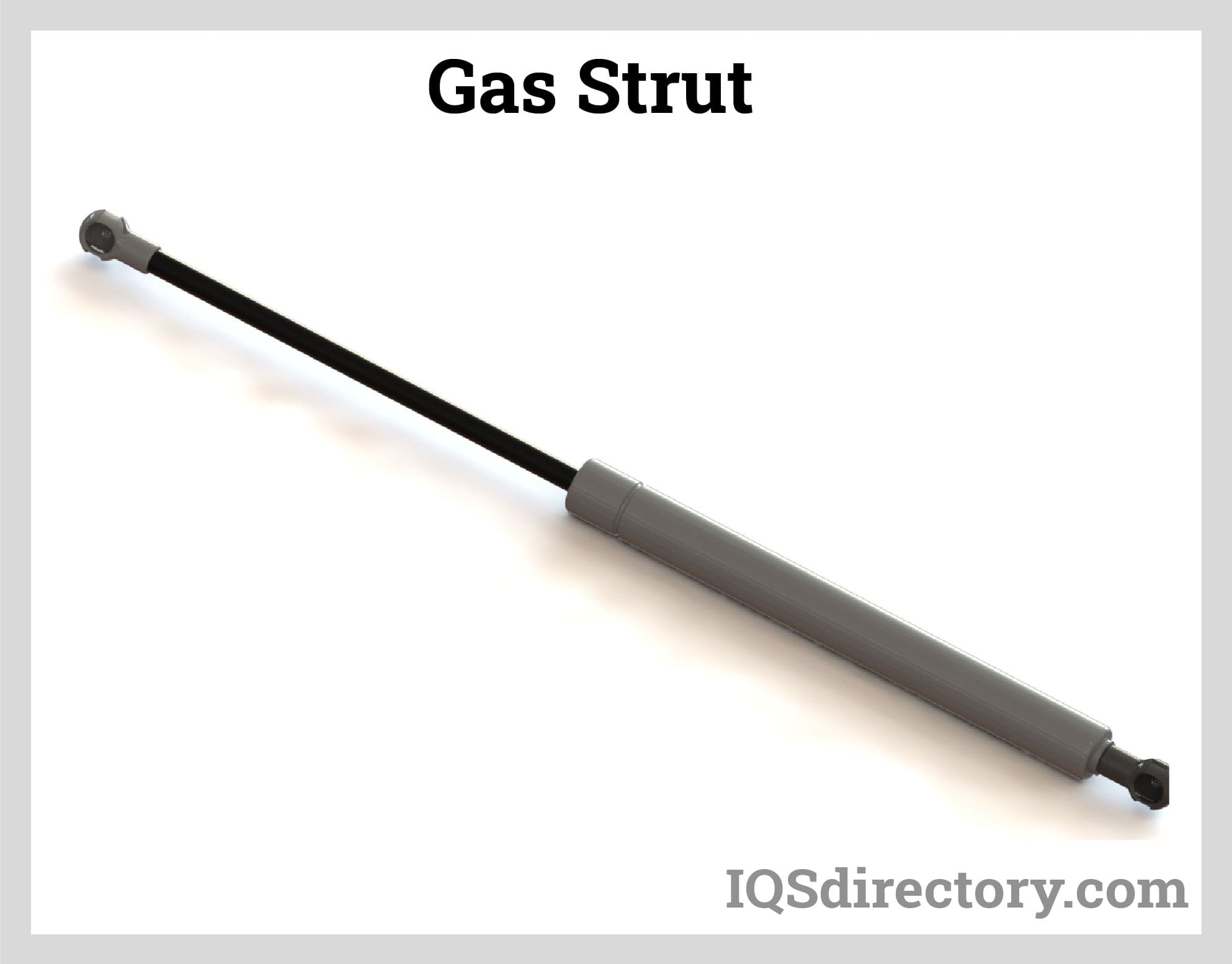

Gas struts adjust chairs and tables and open hatches and panels on boats. They operate with a sliding piston and rod and contain highly pressurized nitrogen gas with oil-based lubrication. Gas struts, sometimes known as gas springs, rams, or dampers, make it simple to raise awkward or heavy things. They are typically used to raise heavy toolbox lids, tailgates, horizontally opening windows, and vehicle bonnets or boots. Pressurized nitrogen serves as a spring in gas struts, while a small amount of special oil serves as a damper when a strut extends to its maximum length. Read More…

Isotech offers a complete line of gas springs for most applications. From steel to stainless steel AISI 303/304 and AISI 316/316Ti, Isotech has the right product for the job. Gas Springs include tension springs, locking gas springs, realease systems, oil dampers, double-stroke springs, and gas spring accessories. Contact us today for more information!

More Gas Strut Manufacturers

A strut should always be installed with the shaft at the bottom and the main body at the top since the oil also lubricates the shaft and closes the cylinder against gas loss. Gas struts make it possible to open and close items quickly and smoothly. Over time, struts are prone to leak, decreasing their effectiveness. Most individuals don't give their gas struts any thought; once they become difficult to use or cease functioning entirely, they are discovered.

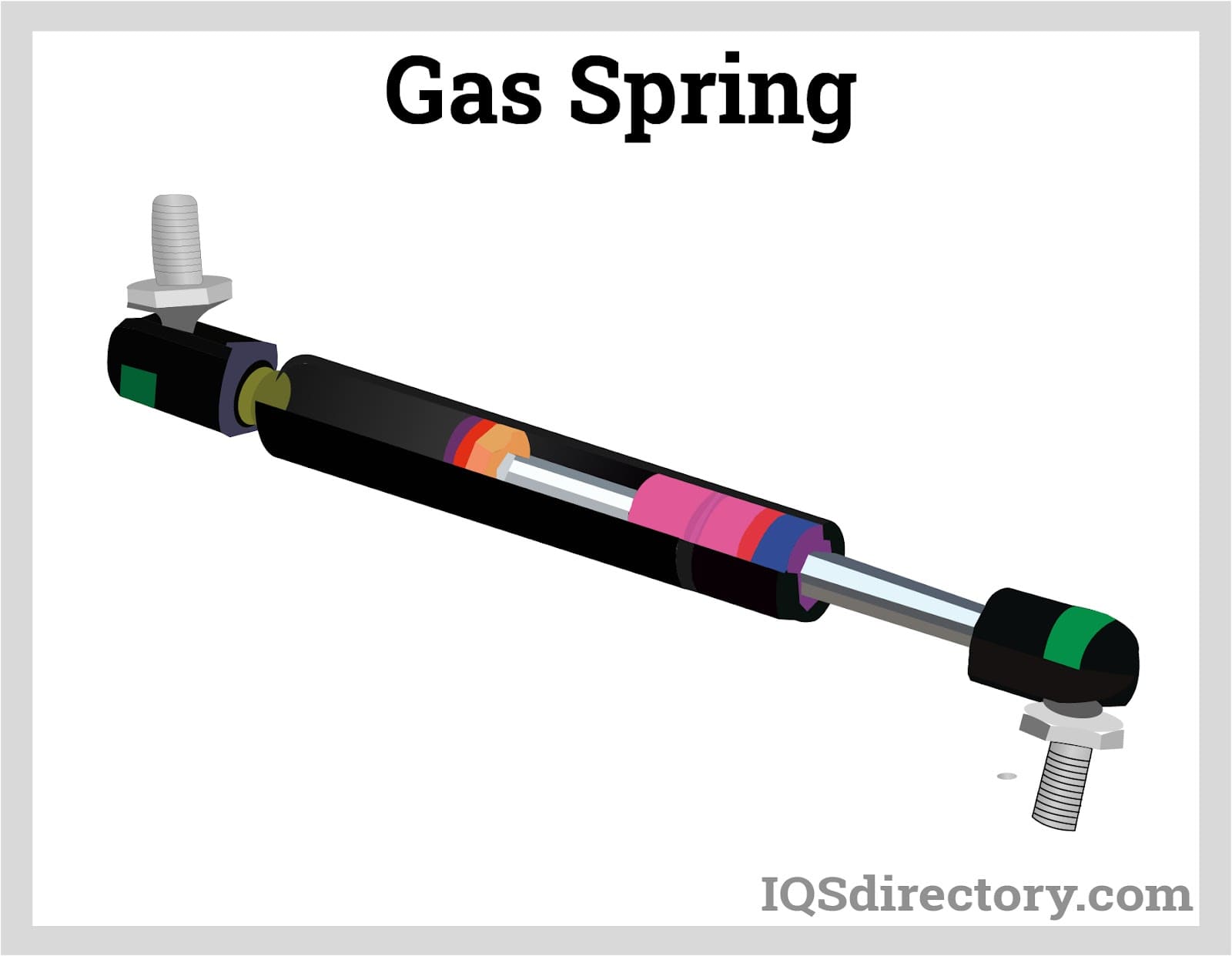

How Gas Struts Operate

Gas struts are used in various applications and are built slightly differently for each. Overall, they all share a functioning based on a piston and rod, much like a hand or bicycle pump. Unlike other hand pumps, the tube through which the piston travels is hermetically sealed to keep the pressurized nitrogen gas inside. The available volume is decreased, the gas is compressed, and the internal pressure rises as the rod is forced into the tube. This compression produces spring-like behavior. Gas can flow across the piston via an opening in the rod-attached piston, which also regulates the speed of extension.

Types of Gas Struts

Standard Gas Struts

The rod is out in the typical gas struts, but the load from the application forces the rod in. Therefore, a gas strut is often installed rod down in the position where they are used the most. This installation practice enables the rod seals to be lubricated by the oil in the gas strut—these work by controlling the gas strut by maintaining a consistent pressure inside the sealed tube.

Side Valve Gas Struts

Similar fundamental ideas apply to side valve gas struts to normal gas struts. Standard and side valve gas struts differ primarily because the latter includes a release valve on the side that can let off the pressure. Time can be saved by releasing the pressure while the gas spring is in use. An Allen key can turn the side valve.

Locking Gas Struts

By twisting a lever or pressing a remote control, a locking gas strut allows a product to be locked in any position (open or closed) while still providing a pushing force similar to that of a compression gas spring. The release force, determined by the 4:1 ratio of the piston rod area to the valve area, is the force needed to activate or deactivate the lock. Therefore, the releasing force equals one-fourth of the piston rod's extension force. However, one must also account for the force necessary to force the seals loose during actuation, which raises the releasing force.

Friction Lock Gas Struts

Gas struts with a friction lock can be quickly locked off in any position with the help of a sizable, simple-to-grasp nut. When unlocked, the spring behaves exactly like a regular compression gas strut.

Lock Open Gas Struts

These have a guard that snaps into place when the rod reaches its full extension, locking the gas strut in the open position. Likewise, when the gas strut reaches its full length, this sleeve automatically retracts into position, securing your application in the open position. This retraction is ideal if you have, for instance, a heavy hatch or lid that might be exposed to wind loading or other intermittent force because it provides a safety locking function.

Applications of Gas Struts

Gas Struts for Doors

To help them open readily under pressure and swiftly return to a closed position when not in use, doors in homes, schools, and workplaces typically include some traction or pull-type gas strut. On the other hand, cabinet doors and access hatches frequently need to perform the exact opposite function, allowing heavy objects to be lifted with ease and fully open until they are manually closed again. As a result, locking gas struts are frequently utilized in both scenarios.

Gas Struts for Cars

The design of some cars' hoods, panels, and compartments may have many sets of gas struts, although the boot-lifting mechanisms are by far the most prevalent application. In particular, nearly all hatchbacks and estate cars will have gas struts affixed to the rear assembly, helping to lift, support, and lower their heavy tailgates smoothly and effortlessly.

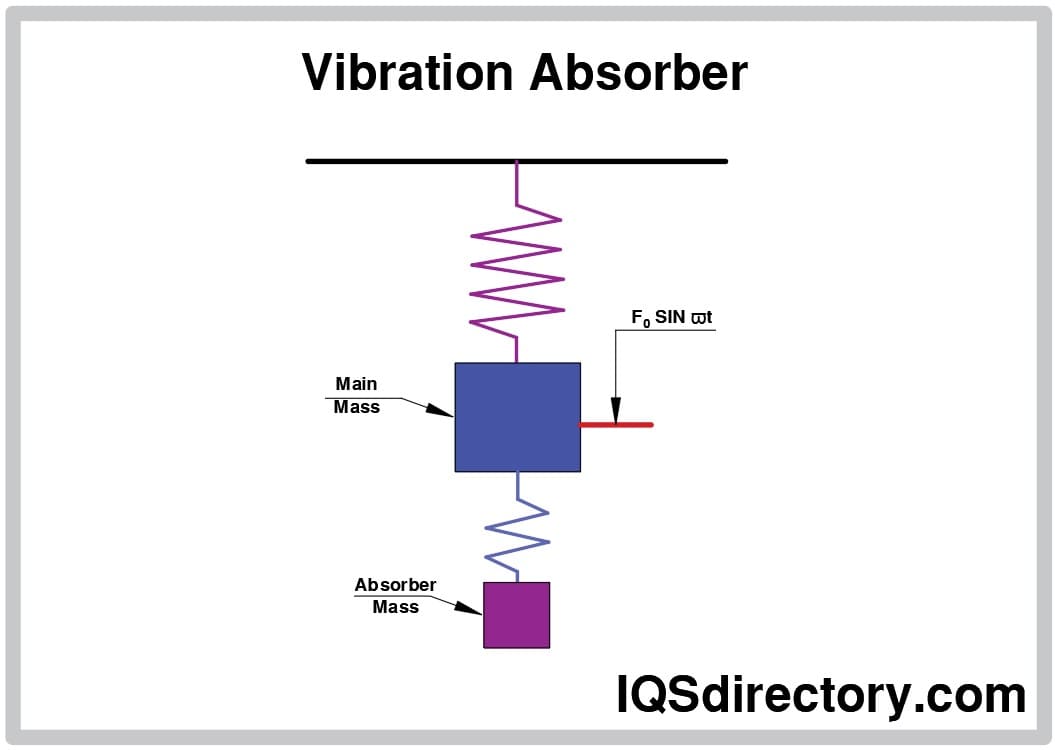

Gas Struts for Chairs

The gas struts frequently used in office chairs are typically set up in a "damping" configuration, where more resistance is encountered when lowering the chair and less is encountered when raising it. While sitting in it, the seat's downward movement is muted by this, but when you're not, it naturally allows the seat to spring back to its initial position.

Benefits of Gas Struts

- Greater force in a smaller area; greater force on contact

- Integrated damping for controlled motion

- Gas struts run on stored energy and don't need a power source.

- Gas struts are separate units and don't need hoses, actuators, or pumps.

- Pressure measurements and changes are possible.

- Long cycle life and overhaul capability

- It can be made to function in a variety of severely corrosive and polluted situations.

Choosing the Correct Gas Strut Supplier

To ensure you have the most productive outcome when purchasing gas struts from a gas strut supplier, it is important to compare several companies using our directory of gas strut suppliers. Each gas strut supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each gas strut business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple gas strut companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

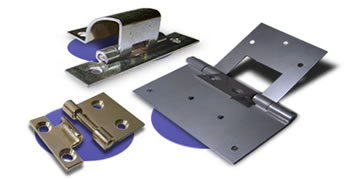

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services