More Gas Spring Manufacturers

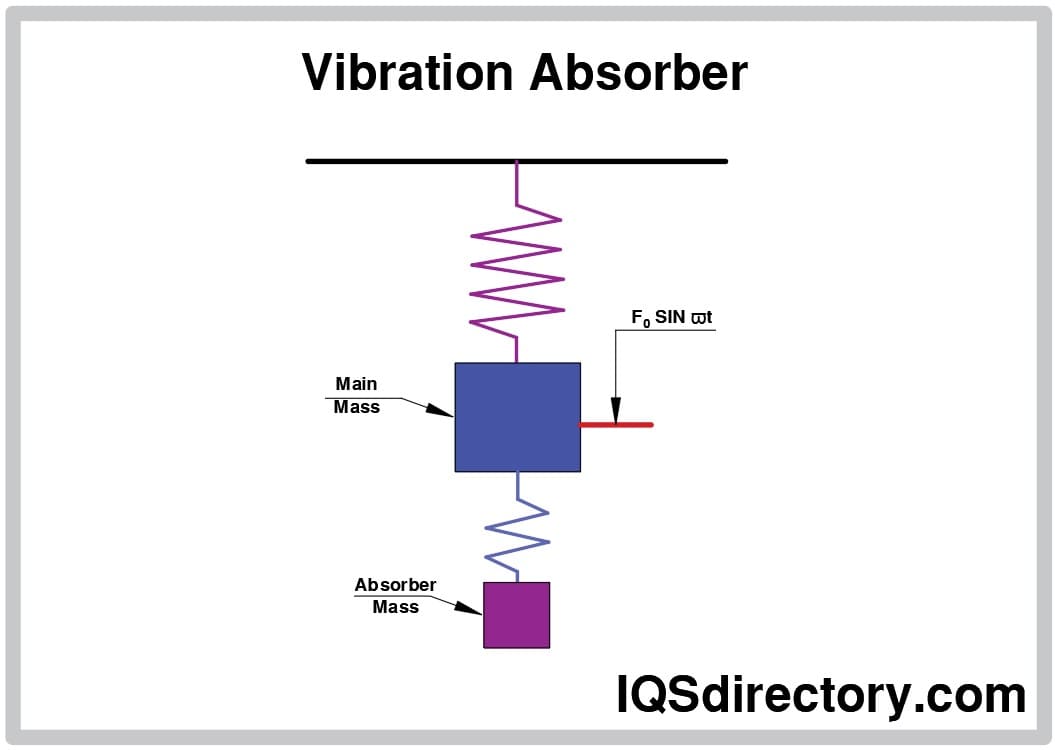

When comparing gas springs to traditional mechanical springs, it’s important to understand the differences in operation and performance. Standard mechanical springs—like coil and leaf springs—rely on elastic deformation to absorb energy. In contrast, gas springs, sometimes called pneumatic springs or gas struts, absorb impacts through the pneumatic energy of high-pressure gas (usually nitrogen) sealed within a cylinder. This unique energy-absorption mechanism gives gas springs distinct advantages for shock absorption, vibration dampening, and controlled motion across countless industries.

Gas springs operate similarly to air cylinders or pneumatic actuators, utilizing a piston that moves within a cylinder as gas pressure changes. When force is applied, the piston compresses the gas, storing energy and providing a smooth, controlled motion. This principle makes gas springs ideal for applications requiring reliable, repeatable force and motion control.

Today, gas springs are indispensable in applications such as shock absorption, dampening, and force exertion. They frequently replace mechanical springs to lift, lower, open, close, and adjust various components. Their versatility and efficiency make them a preferred choice for engineers and manufacturers seeking custom gas spring solutions tailored to specific requirements.

Numerous industries rely on gas springs for essential functions. In aerospace and aviation, gas springs support landing gear, cargo door mechanisms, and cabin storage. The healthcare sector leverages gas springs in hospital beds, medical chairs, and adjustable tables for ergonomic and safe patient handling. Office furniture manufacturers integrate gas springs into adjustable chairs and monitor arms for smooth height and tilt adjustments. Marine and agricultural equipment utilize corrosion-resistant gas springs for hatches, covers, and machinery. The automotive industry depends on gas springs for hood supports, trunk lids, hatchbacks, tailgates, and even in seat mechanisms and suspension systems. Beyond these, gas springs are found in applications such as tanning beds, awning extensions, industrial machinery, and specialized manufacturing equipment.

History of Gas Springs

The origins of gas springs trace back to the late 19th century. The initial gas springs were patented in 1891 by Paul Giffard, a Parisian engineer who designed them for firearms. Giffard’s design harnessed gas pressure to enhance the force with which handguns fired bullets, introducing a new level of power and control. Interestingly, similar innovations had appeared in the United States as early as 1875, though these early prototypes initially attracted little industry attention.

It wasn’t until the mid-1900s that gas springs gained widespread popularity. Automotive engineers recognized their potential and adapted gas springs for use in car hoods and trunks, revolutionizing vehicle design and consumer convenience. This breakthrough sparked a global trend, inspiring manufacturers to explore gas spring applications in fields ranging from furniture and healthcare to aviation and industrial automation.

Gas Spring Design & Engineering

Modern gas spring manufacturing relies heavily on advanced engineering tools. Most manufacturers use 3D CAD software or similar design platforms to achieve maximum precision and quality during the development of gas springs. Meticulous design ensures that each gas spring meets the stringent requirements of its intended application, whether it’s for heavy-duty industrial equipment, medical devices, or consumer products.

Key Gas Spring Materials

Body Materials

Manufacturers typically produce gas spring cylinders and rods from high-quality metals such as stainless steel and aluminum. Stainless steel gas springs are especially prevalent due to their outstanding corrosion resistance, making them suitable for marine, food processing, and medical environments. Aluminum gas springs offer a lightweight alternative, ideal for weight-sensitive applications such as aerospace and portable equipment. In some cases, manufacturers utilize additional materials like EPDM synthetic rubber and polyurethane for seals and bushings, enhancing durability and performance.

To further improve environmental resistance, manufacturers may apply protective coatings such as chrome plating or black nitride finishes. These coatings bolster the spring’s longevity and reliability, especially in corrosive or high-wear environments. When selecting a gas spring, consider the expected environmental exposure—will the gas spring operate outdoors, in wet conditions, or near chemicals? The right material and finish will ensure optimal lifespan and performance.

Gas Material

The gas used inside the spring is another critical factor. Manufacturers typically select either nitrogen gas or carbon dioxide for gas springs. Nitrogen gas springs are favored for their inert properties; nitrogen doesn’t react chemically, is non-flammable, and is stable under pressure, making it the industry standard. Carbon dioxide is sometimes used in specialized applications due to its harmless nature and compatibility with certain manufacturing processes. The choice of gas affects performance, pressure stability, and safety.

Design Considerations & Customization

Designing an effective gas spring is a balancing act between performance, durability, and the specific requirements of the application. Key factors include:

- Gas volume and pressure: The volume of gas in the cylinder and its pressure determine the force output and stroke length.

- Cycle requirements: How many actuations per minute/hour, and over what lifespan?

- Actuation speed and dampening: Does the application require rapid motion, slow controlled movement, or vibration dampening?

- Environmental conditions: Will the spring face extreme temperatures, moisture, chemicals, or dirt?

- Regulatory compliance: For industries like food, beverage, or pharmaceuticals, does the gas spring need to meet FDA or similar standards?

Manufacturers customize gas springs by adjusting:

- Overall size (length and diameter)

- Extended and compressed lengths

- Load capacity and force output

- Stroke length

- Operating pressure

- Cycle life and durability features

- Operating temperature range

- Type of end fittings and mounting options

Gas cylinder sizes can range from compact two-inch springs for small enclosures to several feet long for heavy industrial doors. Load capacities vary widely, from as little as 100 pounds to over 80,000 pounds in specialized industrial or automotive applications. Manufacturers can also design custom gas springs for unique requirements, including special mounting configurations, finishes, and performance attributes.

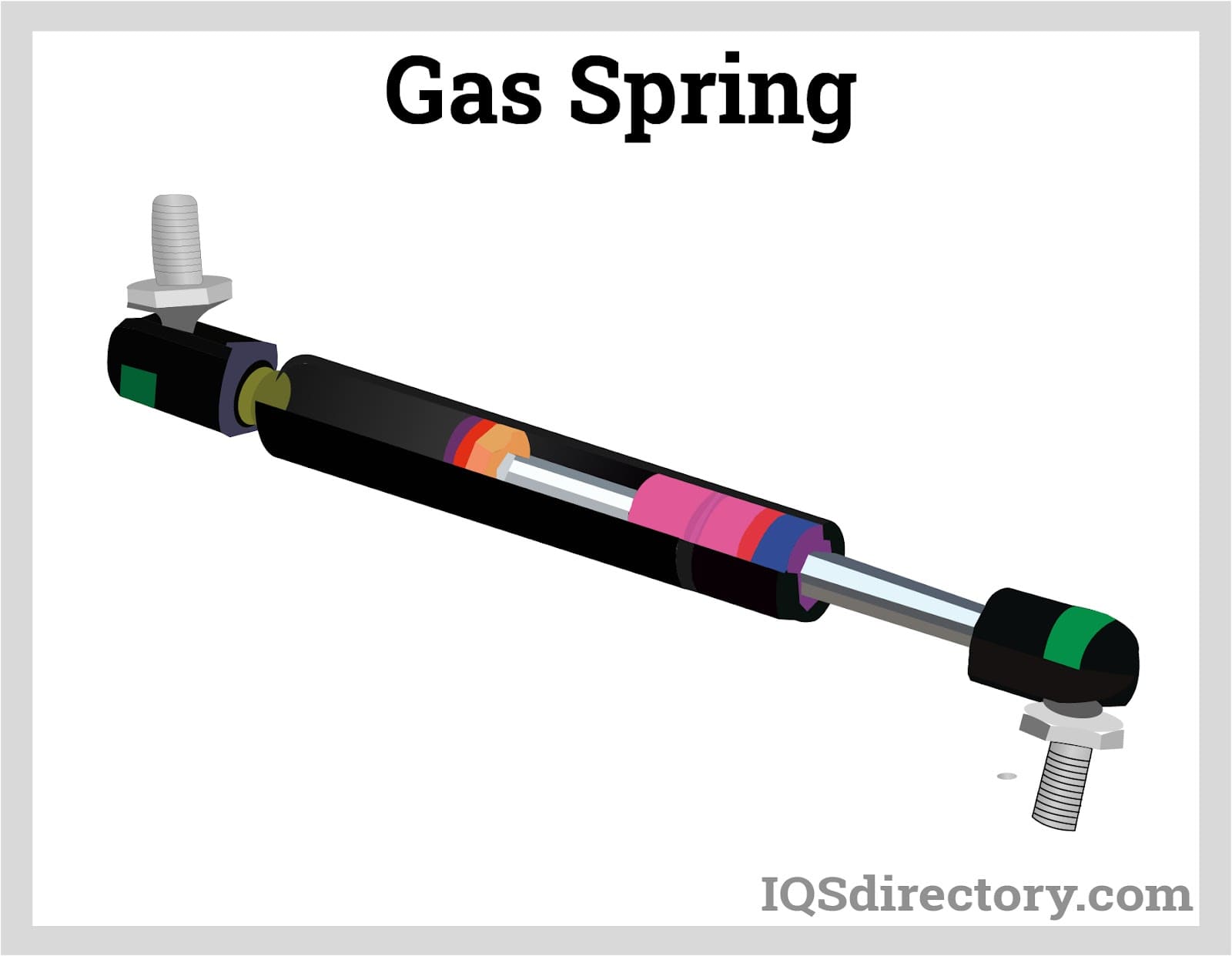

Gas Spring Features & Internal Components

Despite their simple appearance, gas springs feature a sophisticated internal design. Every gas spring consists of several essential components:

- Cylindrical body: Houses the compressed gas and provides structural strength.

- Piston rod: Extends and retracts from the cylinder, transmitting force to the desired object.

- Piston head: Divides the cylinder into two compartments and ensures airtight separation.

- Seals and O-rings: Maintain pressure and prevent gas leakage.

- Intake/outlet valves: Regulate gas flow for smooth operation and dampening.

- Guide bushings and bearings: Reduce friction and ensure precise movement.

- End fittings: Enable secure attachment to mounting points.

The cylinder’s polished interior surface reduces friction and wear, ensuring silent, smooth movement of the piston rod. The seals—often made from advanced polymers—are crucial for maintaining pressure and extending gas spring life, especially in high-cycle environments.

When force is applied, the rod is driven into the cylinder, compressing the gas and creating a cushioning effect. For example, when a car encounters a bump, the gas springs in the suspension compress and absorb the shock, smoothing out the ride for passengers. This controlled, dampened motion is why gas springs are preferred in applications where precision and comfort are essential.

Types of Gas Springs

Gas springs come in a wide variety of types, each engineered for specific functions and industry requirements. Understanding the available types will help you select the right component for your application. Common gas spring types include:

- Compression Gas Springs: The most common type, compression gas springs provide a pushing force as the piston compresses the gas, offering cushioning and controlled extension. Widely used in automotive hoods, hatchbacks, and machine guards.

- Extension Gas Springs: Designed for pulling applications, extension gas springs push the rod outward, isolating movement and maintaining separation between components. Used in doors, hatches, and industrial equipment.

- Tension Gas Springs: Sometimes called reverse-acting gas springs, these maintain tension and are ideal for applications requiring constant pulling force, such as cabinet doors, furniture components, and adjustable arms.

- Locking Gas Springs: Feature a mechanism that allows the rod to lock in place when fully extended, providing precise control and stability. Common in hospital beds, adjustable chairs, and transport equipment.

- Adjustable Gas Springs: Allow the force and stroke to be fine-tuned during installation or use. Frequently found in medical equipment, emergency gurneys, and ergonomic seating.

- Reducible Gas Springs: Enable users to reduce the internal gas pressure, adjusting the force output as needed. Useful for prototyping and applications with variable loads.

- Tool and Die Gas Springs: Heavy-duty gas springs designed for stamping, forming, and die cutting in industrial presses. They deliver high force in compact packages and are built for long cycle life.

- Gas Spring Dampers: Also known as motion dampers, these control speed and absorb energy without providing significant force. Used in lids, covers, and machinery for smooth, gradual motion.

- Gas Struts: Similar to compression gas springs, gas struts are versatile components for lifting, supporting, and counterbalancing. Common in automotive, aerospace, and industrial equipment.

- Lift Gas Springs: Specifically designed to assist with vertical lifting operations, such as supporting heavy panels, machinery covers, and hospital beds.

Not sure which type is right for your project? Explore our comprehensive gas spring types guide or ask our experts for personalized recommendations.

Advantages of Gas Springs over Mechanical and Fluid Systems

Gas springs compete with a variety of mechanical and fluid-based systems, such as coil springs, leaf springs, hydraulic cylinders, and pneumatic actuators. While all these alternatives store and release mechanical energy, gas springs offer several unique advantages:

- Smooth and Controlled Motion: Thanks to built-in dampening, gas springs eliminate abrupt jolts and rebounds. This is critical in applications like automotive suspension, ergonomic furniture, and medical equipment where comfort and precision are essential.

- Compact and Lightweight Design: Gas springs are lighter and more compact than equivalent coil or leaf springs, simplifying integration and aiding weight reduction—a key priority in automotive and aerospace engineering.

- Versatility and Adjustability: Unlike leaf springs, gas springs can be engineered for precise force and stroke, providing custom solutions for everything from industrial automation to consumer electronics.

- Low Maintenance and High Reliability: With fewer moving parts and a sealed design, gas springs require minimal maintenance and are less prone to failure than hydraulic or pneumatic systems, which can leak or require regular servicing.

- Energy Efficiency: Gas springs do not require external power sources or pumps, making them more energy-efficient and cost-effective over time.

- Reduced Installation Complexity: Their self-contained design allows for quick installation and easy retrofitting into existing systems.

- Wide Range of Applications: Gas springs are suitable for industries as diverse as aerospace, automotive, furniture, industrial machinery, healthcare, marine, and more.

If you’re weighing the pros and cons of gas springs versus coil springs, hydraulic cylinders, or pneumatic actuators, consider how gas springs can deliver smoother operation, greater adjustability, and lower lifecycle costs for your system. Learn more about the benefits of gas springs or request a quote for your application.

Gas Spring Accessories & Mounting Options

To maximize the performance and versatility of gas springs, a range of accessories and mounting options are available. Selecting the right accessories ensures secure installation and reliable, long-term operation in your specific environment.

Nylon Socket End Fittings

Nylon socket end fittings offer a robust yet flexible connection between the gas spring and its mounting point. Their durable, low-friction properties make them ideal for applications requiring smooth, quiet operation, such as office chairs, medical devices, and laboratory equipment.

Stainless Steel Socket End Fittings

Stainless steel socket end fittings provide exceptional strength and resistance to corrosion. They are essential for applications exposed to harsh environments, including marine, food processing, chemical plants, and outdoor machinery. Their reliability and longevity make them a staple for critical and heavy-duty uses.

O-Ring Seals

O-ring seals are vital for maintaining gas pressure and preventing leaks. High-performance seals ensure consistent force output and protect the spring’s internal components from contamination by dust, moisture, or chemicals. In high-cycle or safety-critical environments, quality seals are non-negotiable.

Mounts & Mounting Brackets

Proper mounting is crucial for optimal gas spring performance. Mounts and brackets come in a variety of designs—side mounts, end mounts, pivot mounts, and multi-angle brackets—to accommodate different installation requirements. Choosing the right bracket allows for precise alignment and secure attachment, which enhances system safety and efficiency.

Ball Receivers

Ball receivers create a ball-and-socket joint, offering multidirectional motion and flexibility. They’re commonly used in automotive hoods, trunk lids, and any application requiring frequent pivoting or adjustment.

Connectors

A wide selection of connectors (eyelet, clevis, threaded, and more) allows gas springs to interface with different mechanical systems. The correct connector ensures secure attachment, ease of maintenance, and compatibility with your equipment.

Wondering which accessories you need? Start by assessing your load requirements, motion range, environmental exposure, and installation constraints. For heavy-duty, corrosive, or custom applications, stainless steel fittings and specialty connectors may be necessary. Contact a gas spring accessory expert or browse our comprehensive accessory catalog for more details.

Accessories can be sourced from specialized manufacturers, authorized distributors, and reputable online marketplaces. Consider working with suppliers who offer technical guidance and support, ensuring you select the ideal combination of gas spring and accessory for your project.

Proper Care, Installation & Maintenance Tips

Ensuring the longevity and optimal performance of your gas springs starts with proper care and usage. Here’s how to keep your gas springs functioning at their best:

- Observe Design Limits: Use gas springs only within their rated load capacities, temperature ranges, and environmental tolerances.

- Regular Inspection: While gas springs require little maintenance, periodic inspection for signs of wear, leaks, or damage is recommended. Catching issues early helps prevent unexpected failures.

- Correct Installation: Follow manufacturer guidelines for mounting orientation, alignment, and torque on fittings. Incorrect installation can reduce lifespan or cause malfunction.

- Avoid Unauthorized Modifications: Never attempt to open, refill, or modify a gas spring unless explicitly designed for adjustment.

- Safe Disposal: When a gas spring reaches end-of-life, safely release internal pressure and recycle according to local regulations. Specialized recycling may be required for some industrial gas springs.

Industry Standards & Compliance

Compliance with recognized standards is essential for gas spring safety, reliability, and interoperability across industries. In the United States, agencies such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines covering design, material quality, manufacturing, and performance testing for gas springs. Other relevant standards may include SAE (Society of Automotive Engineers) and ASTM (American Society for Testing and Materials) specifications, especially for automotive and aerospace applications.

Using gas springs that fail to meet these standards can result in:

- Reduced performance and reliability

- Shortened service life

- Potential safety hazards and risk of injury

- Higher maintenance and replacement costs

- Legal and regulatory complications

Conversely, gas springs that are certified to ANSI, ISO, or other relevant standards offer peace of mind. They have passed rigorous testing for load capacity, cycle life, corrosion resistance, and safety. Compliance also ensures compatibility and ease of integration, with clear documentation and user guidelines provided for installation and operation.

If your application is regulated or mission-critical, always verify that your gas springs meet the necessary certifications. Learn more about certified and standards-compliant gas springs for specific industries.

How to Choose the Right Gas Spring Supplier

Finding the best gas spring manufacturer or supplier is a crucial step in any successful project. To help you, we’ve assembled a list of trusted gas spring manufacturers. Scroll down to find supplier profiles, direct contact details, and links for quick inquiries.

Before contacting potential suppliers, it’s wise to prepare a detailed specifications list. Outline:

- Project budget and timeline

- Required quantities and delivery schedule

- Performance specifications (load, stroke, life cycle, material, etc.)

- Mounting and accessory needs

- Environmental conditions (temperature, exposure, etc.)

- Compliance or certification requirements

- Post-delivery support (spare parts, warranties, technical support)

After compiling your requirements, use this list to identify suppliers with the capabilities, product range, and support you need. Select several promising candidates and reach out to discuss your application in detail. During discussions, reference your list to ensure all needs are addressed. Compare proposals based on product quality, customization options, pricing, lead times, and after-sales support before making your final choice.

Common Gas Spring Questions & Buying Guide

- What are the main differences between gas springs and hydraulic dampers? Gas springs use compressed gas to provide force, while hydraulic dampers primarily control speed and absorb energy without significant force output.

- Can gas springs be used in outdoor or corrosive environments? Yes—choose stainless steel gas springs or those with protective coatings for maximum corrosion resistance.

- What maintenance do gas springs require? While maintenance is minimal, regular inspections and correct installation are key to maximizing lifespan.

- Can I get gas springs with custom end fittings or finishes? Absolutely! Many manufacturers offer custom options to fit your exact requirements.

Ready to move forward? Request a quote for your gas spring project or contact our experts for personalized assistance.

What is a gas spring and how does it work?

A gas spring is a type of spring that uses high-pressure gas, typically nitrogen, sealed within a cylinder to provide force. When force is applied, a piston moves inside the cylinder, compressing the gas and providing a smooth, controlled motion ideal for lifting, lowering, opening, closing, and adjusting components.

What are the main advantages of gas springs over mechanical and hydraulic systems?

Gas springs offer smoother and more controlled motion, are compact and lightweight, require low maintenance, and are highly versatile and adjustable. They do not need external power sources and are easy to install, making them cost-effective and suitable for a wide range of applications.

In what industries are gas springs commonly used?

Gas springs are widely used in automotive, aerospace, healthcare, marine, office furniture, agricultural, and industrial machinery industries. Typical applications include automotive hoods and trunks, medical beds and chairs, aircraft storage compartments, marine equipment, and adjustable seating.

How do I select the appropriate gas spring for my application?

When choosing a gas spring, consider the required force output, stroke length, load capacity, operating environment, material and finish, cycle requirements, and mounting needs. Manufacturers can customize size, end fittings, finishes, and performance features for specific requirements.

What maintenance do gas springs require?

Gas springs require minimal maintenance. Regular visual inspections for wear, leaks, or damage are recommended, as well as following correct installation procedures. Modifications should not be attempted unless the design allows, and gas springs should be safely recycled at end-of-life.

Can gas springs be used in outdoor or corrosive environments?

Yes, gas springs made from stainless steel or those with protective coatings like chrome plating or black nitride finishes are suitable for outdoor or corrosive environments. These materials provide enhanced corrosion resistance for marine, food processing, and other harsh settings.

Are custom gas spring options available?

Yes, many manufacturers offer custom gas springs with specific dimensions, force output, strokes, end fittings, finishes, and mounting configurations to meet unique project requirements.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services